The batch certificate is a quality guarantee that companies give their customers that the items they supply are of the expected quality and will not compromise the user.

In the laboratory glassware industry, volumetric material is the main target of this type of certification, and companies that produce items such as volumetric flasks, cylinders, etc. often issue a certificate of conformity in which they admit that the items have the expected capacity and that this is within the imposed tolerances.

On Vilabo’s batch certificate there are various nomenclatures that may cause doubts in the user’s mind. In this article we will clarify the most common ones.

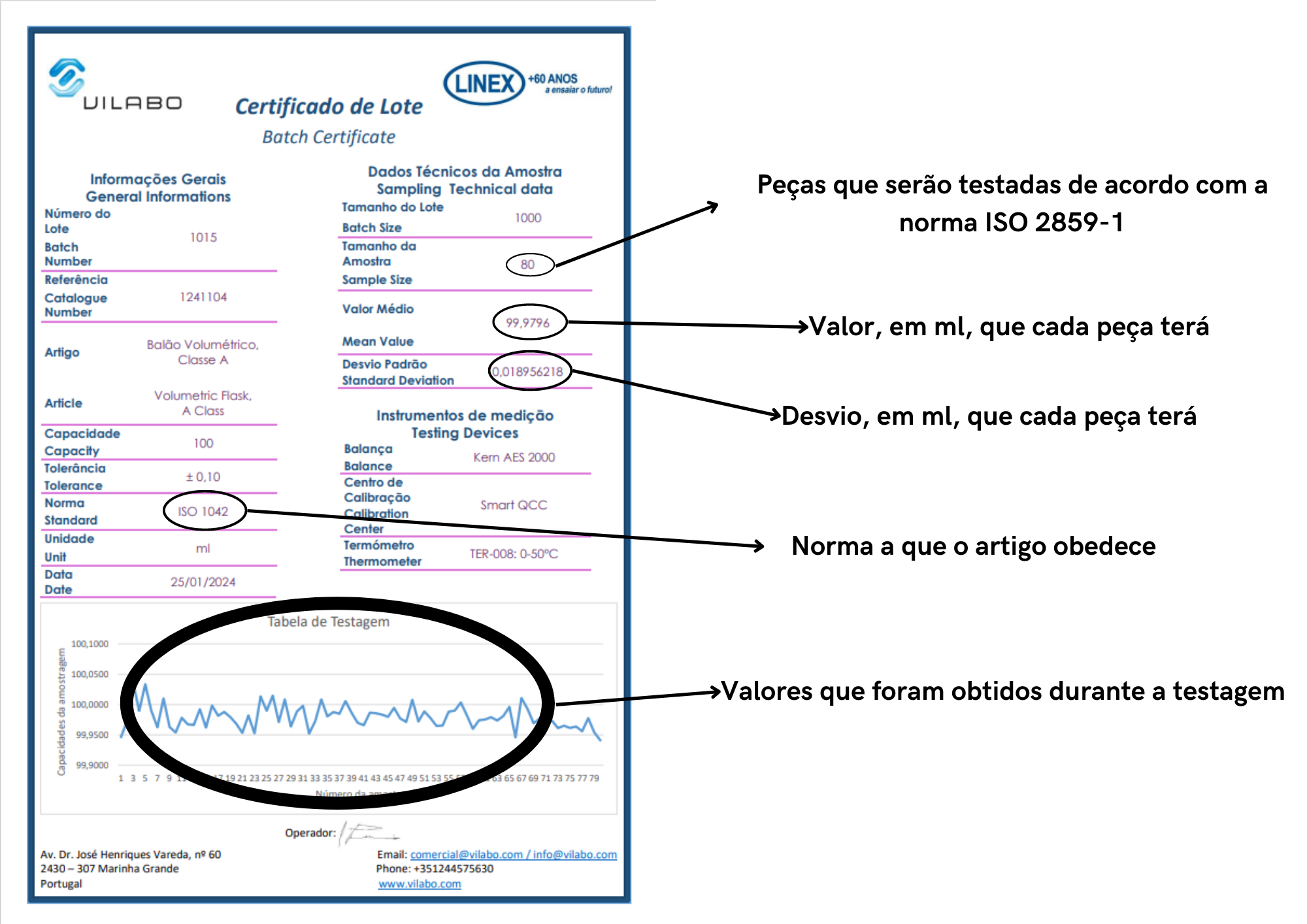

For the sake of illustration, the article will use the batch certificate issued by Vilabo no. 1015 for the article Volumetric Flask 100 ml CL A.

Standard

The standard that is indicated on the batch certificate indicates the standard to which the article conforms, both in terms of volume (in milliliters) and the acceptable dimensions that the article must have. In the case of the image, ISO 1042 is the standard by which volumetric flasks are manufactured.

Sampling table

The sampling table shows how the articles were tested. The table is limited on the vertical axis by the maximum and minimum limits a part will have. These limits are provided by the standard that the items comply with, which in the case of the image shown is a 100 milliliter (ml) Class A volumetric flask that has a tolerance of 0.1 ml, so from the starting point of 100 ml its maximum limit will be 100.1 ml and its minimum limit will be 99.9 ml. All values within this range are considered acceptable; any value outside this range represents a non-conformity.

As we can see from the table in the image, there were no non-conformities.

Sample size

The sample size is a value that is not calculated at random. The number of skins that will be tested varies depending on the number of skins in the batch. The larger the batch, the greater the number of pieces tested. This number is in accordance with ISO 2859-1.

Mean Value

The mean value is the sum of the capacity in ml of the parts tested divided by the number of items tested. This value represents the capacity in ml that all the parts in a given batch will have on average. In the case of the image, we can assume that for the batch in question all the parts will have a capacity of 99.9796 ml. This value can never be greater than the sum or subtraction of the target capacity (which is 100 ml) and its tolerance (which is 0.1 ml). If this happens, the batch will be rejected and, consequently, your parts will not have been correctly gauged to the required volumes. Example: All values within the following range are considered acceptable. 100 ml ±0.1 ml=[99.9 ;100.1]

It is also very difficult to have batches of the same capacity with different serial numbers but identical mean values and standard deviations (see below). If this happens, we could be dealing with a company that doesn’t test its volumetric material properly, thus failing to guarantee the quality of its article.

Standard deviation

![]()

The standard deviation is a value by which it is assumed that the parts in a given batch vary up or down. Based on the value obtained in the “Average value”, it is expected that the pieces in a given batch will vary on average by the standard deviation.

In the case of the image shown, which belongs to lot 1015 and refers to the item 100 ml volumetric flask, a standard deviation of 0.018956218 ml was obtained, i.e. the flask in this lot could have, on average, a capacity that varies between the sum or subtraction of the average value and the standard deviation: 99.9796 ml ±0.018956218 ml=[ 99.960644 ;99.998556].

It is important to note that, when calculating this range of values, it is not advisable to have values in the range that are outside the tolerance. It should also be noted that under no circumstances should the standard deviation value ever be higher than the tolerance value.